Next: Nonlocal isotropic damage model Up: Material models for tensile Previous: Nonlocal smeared rotating crack

The equivalent strain,

![]() , is a scalar measure derived from the

strain tensor. The choice of the specific expression

for the equivalent strain affects the shape of the elastic domain

in the strain space and plays a similar role to the choice of a yield

condition in plasticity.

The following definitions of equivalent strain are currently supported:

, is a scalar measure derived from the

strain tensor. The choice of the specific expression

for the equivalent strain affects the shape of the elastic domain

in the strain space and plays a similar role to the choice of a yield

condition in plasticity.

The following definitions of equivalent strain are currently supported:

Note that all these definitions are based on the three-dimensional description of strain (and stress). If they are used in a reduced problem, the strain components that are not explicitly provided by the finite element approximation are computed from the underlying assumptions and used in the evaluation of equivalent strain. For instance, in a plane-stress analysis, the out-of-plane component of normal strain is calculated from the assumption of zero out-of-plane normal stress (using standard Hooke's law).

Since the growth of damage usually leads to softening and may induce localization of the dissipative process, attention should be paid to proper regularization. The most efficient approach is based on a nonlocal formulation; see Section 1.5.7. If the model is kept local, the damage law should be adjusted according to the element size, in the spirit of the crack-band approach. When done properly, this ensures a correct dissipation of energy in a localized band of cracking elements, corresponding to the fracture energy of the material. For various numerical studies, it may be useful to specify the parameters of the damage law directly, independently of the element size. One should be aware that in this case the model would exhibit pathological sensitivity to the size of finite elements if the mesh is changed.

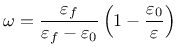

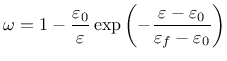

The following damage laws are currently implemented:

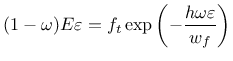

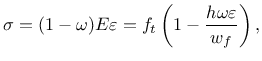

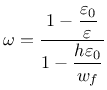

The derivation

has been performed for monotonic loading and uniaxial tension. Under general

conditions,

![]() is replaced by the internal variable

is replaced by the internal variable ![]() ,

which represents the maximum previously reached level of equivalent strain.

,

which represents the maximum previously reached level of equivalent strain.

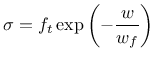

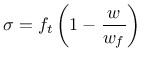

In the list of input variables, the tensile strength ![]() is not specified

directly but through the corresponding strain at peak stress,

is not specified

directly but through the corresponding strain at peak stress,

![]() , denoted by keyword e0. Another input parameter

is the characteristic crack opening

, denoted by keyword e0. Another input parameter

is the characteristic crack opening ![]() , denoted by keyword wf.

, denoted by keyword wf.

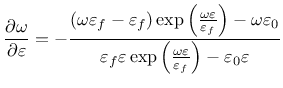

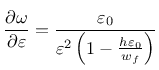

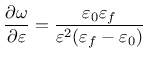

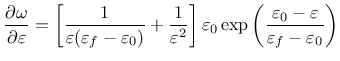

Derivative can be expressed explicitly

Note that parameter damlaw determines which type of damage law should be used, but the adjustment for element size is done only if parameter wf is specified for damlaw=0 or damlaw=1. For other values of damlaw, or if parameter ef is specified instead of wf, the stress-strain curve does not depend on element size and the model would exhibit pathological sensitivity to the mesh size. These cases are intended to be used in combination with a nonlocal formulation. An alternative formulation uses fracture energy to determine fracturing strain.

The model parameters are summarized in Tab. 23. Figure 6 shows three modes of a softening law with corresponding variables.

![\includegraphics[width=0.99\textwidth]{Damage_material_diag.eps}](img303.png) |

| Description | Isotropic damage model for concrete in tension | ||||||||||||||||

| Record Format | Idm1 (in) # d(rn) # E(rn) # n(rn) # [tAlpha(rn) #] [equivstraintype(in) #] [k(rn) #] [damlaw(in) #] e0(rn) # [wf(rn) #] [ef(rn) #] [ek(rn) #] [wk(rn) #] [sk(rn) #] [wkwf(rn) #] [skft(rn) #] [gf(rn) #] [gft(rn) #] [At(rn) #] [Bt(rn) #] [md(rn) #] [ft(rn) #] [ep(rn) #] [e1(rn) #] [e2(rn) #] [nd(rn) #] [maxOmega(rn) #] [checkSnapBack(rn) #] | ||||||||||||||||

| Parameters | - material number | ||||||||||||||||

| - d material density | |||||||||||||||||

| - E Young's modulus | |||||||||||||||||

| - n Poisson's ratio | |||||||||||||||||

| - tAlpha thermal expansion coefficient | |||||||||||||||||

- equivstraintype allows to choose from different definitions

of equivalent strain:

|

|||||||||||||||||

| - k ratio between uniaxial compressive and tensile strength, needed only if equivstraintype=3, default value 1 | |||||||||||||||||

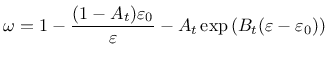

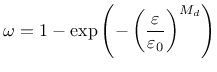

- damlaw allows to choose from different damage laws:

|

|||||||||||||||||

| - e0 strain at peak stress (for damage laws 0,1,2,3), limit elastic strain (for damage law 4), characteristic strain (for damage law 5) | |||||||||||||||||

| - wf parameter controling ductility, has the meaning of crack opening (for damage laws 0 and 1) | |||||||||||||||||

| - ef parameter controling ductility, has the meaning of strain (for damage laws 0 and 1) | |||||||||||||||||

| - ek strain at knee point in bilinear softening type (for damage law 2) | |||||||||||||||||

| - wk crack opening at knee point in bilinear softening type (for damage law 2) | |||||||||||||||||

| - sk stress at knee point in bilinear softening type (for damage law 2) | |||||||||||||||||

| - wkwf ratio of wk/wf |

|||||||||||||||||

| - skft ratio of sk/ft |

|||||||||||||||||

| - gf fracture energy (for damage laws 0-2) | |||||||||||||||||

| - gft total fracture energy (for damage law 2) | |||||||||||||||||

| - At parameter of Mazars damage law, used only by law 4 | |||||||||||||||||

| - Bt parameter of Mazars damage law, used only by law 4 | |||||||||||||||||

| - md exponent used only by damage law 5, default value 1 | |||||||||||||||||

| - ft tensile strength, used only by damage law 7 | |||||||||||||||||

| - ep strain at peak stress, used only by damage law 7 | |||||||||||||||||

| - e1 parameter used only by damage law 7 | |||||||||||||||||

| - e2 parameter used only by damage law 7 | |||||||||||||||||

| - nd exponent used only by damage law 7 | |||||||||||||||||

| - griff_n uniaxial compression/tensile ratio for Griffith's criterion | |||||||||||||||||

| - maxOmega maximum damage, used for convergence improvement (its value is between 0 and 0.999999 (default), and it affects only the secant stiffness but not the stress) | |||||||||||||||||

| - checkSnapBack parameter for snap back checking, 0 no check, 1 check (default) | |||||||||||||||||

| Supported modes | 3dMat, PlaneStress, PlaneStrain, 1dMat | ||||||||||||||||

| Features | Adaptivity support | ||||||||||||||||

Borek Patzak