Drucker-Prager model - DruckerPrager

The Drucker-Prager plasticity model1 is an isotropic elasto-plastic model based

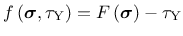

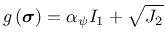

on a yield function

|

(19) |

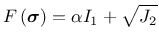

with the pressure-dependent equivalent stress

|

(20) |

As usual,

is the stress tensor,

is the stress tensor,

is the yield stress

under pure shear, and

is the yield stress

under pure shear, and  and

and  are the first invariant and second

deviatoric invariant of the stress tensor.

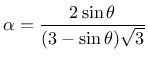

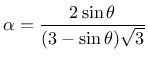

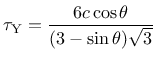

The friction coefficient

are the first invariant and second

deviatoric invariant of the stress tensor.

The friction coefficient  is a positive parameter that

controls the influence of the pressure on the yield limit, important for

cohesive-frictional materials such as concrete, soils or other

geomaterials. Regarding Mohr-Coulomb plasticity, relation to cohesion,

is a positive parameter that

controls the influence of the pressure on the yield limit, important for

cohesive-frictional materials such as concrete, soils or other

geomaterials. Regarding Mohr-Coulomb plasticity, relation to cohesion,  , and

the angle of friction,

, and

the angle of friction,  , exists for the Drucker-Prager model

, exists for the Drucker-Prager model

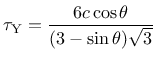

|

|

|

(21) |

|

|

|

(22) |

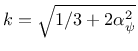

The flow rule is derived from the plastic potential

|

(23) |

where

is the dilatancy coefficient. An associated

model with

is the dilatancy coefficient. An associated

model with

would overestimate the dilatancy of

concrete, so the dilatancy coefficient is usually chosen smaller than the

friction coefficient.

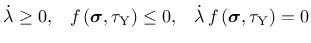

The model is described by the equations

would overestimate the dilatancy of

concrete, so the dilatancy coefficient is usually chosen smaller than the

friction coefficient.

The model is described by the equations

|

(28) |

which represent the linear elastic law, hardening law, evolution laws

for plastic strain and hardening variable, and the

loading-unloading conditions.

In the above,

is the elastic stiffness

tensor,

is the elastic stiffness

tensor,

is the strain tensor,

is the strain tensor,

is the plastic strain tensor,

is the plastic strain tensor,

is the plastic multiplier,

is the plastic multiplier,

is the unit

second-order tensor,

is the unit

second-order tensor,

is the

deviatoric stress tensor,

is the

deviatoric stress tensor,  is the hardening variable, and a

superior dot marks the derivative with respect to time.

The flow rule has the form given in Eq. (26) at all

points of the conical yield surface with the exception of its vertex,

located on the hydrostatic axis.

is the hardening variable, and a

superior dot marks the derivative with respect to time.

The flow rule has the form given in Eq. (26) at all

points of the conical yield surface with the exception of its vertex,

located on the hydrostatic axis.

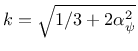

For the present model, the evolution

of the hardening variable can be explicitly linked to the plastic

multiplier.

Substituting the flow rule

(26) into Eq. (27) and computing the norm

leads to

|

(29) |

with a constant parameter

, so the

hardening variable is proportional to the plastic multiplier.

For

, so the

hardening variable is proportional to the plastic multiplier.

For

, the associated

, the associated  -plasticity model

is recovered as a special case.

-plasticity model

is recovered as a special case.

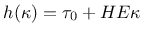

In the simplest case of linear hardening, the hardening function is a

linear function of  , given by

, given by

|

(30) |

where  is the initial yield stress, and

is the initial yield stress, and  is the

hardening modulus normalized with the elastic modulus.

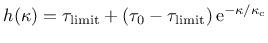

Alternatively, an exponential hardening function

is the

hardening modulus normalized with the elastic modulus.

Alternatively, an exponential hardening function

|

(31) |

can be used for a more realistic description of hardening.

The stress-return algorithm is based on the Newton-iteration.

In plasticity, this is commonly called Closest-Point-Projection (CPP),

and it generally leads to quadratic convergence.

The implemented algorithm is convergent in any stress case, but

in the vicinity of the vertex region, quadratic convergence might be

lost because of insufficient regularity of the yield function.

The algorithmic tangent stiffness matrix is implemented for both the

regular case and the vertex region.

Generally, the error decreases quadratically (of course only asymptotically).

Again, in the vicinity of the vertex region, quadratic convergence

might be lost due to insufficient regularity.

Furthermore, the tangent stiffness matrix does not always exist for

the vertex case. In these cases, the elastic stiffness is used

instead.

It is generally safer (but slower) to use the elastic stiffness if you

encounter any convergence problems, especially if your problem is

tension-dominated.

Table 8:

DP material - summary.

| Description |

DP material |

| Record Format |

DruckerPrager num(in) #

d(rn) # tAlpha(rn) # E(rn) # n(rn) #

alpha(rn) # alphaPsi(rn) # ht(in) #

iys(rn) # lys(rn) # hm(rn) # kc(rn) # [ yieldtol(rn) #] |

| Parameters |

- num material model number |

| |

- d material density |

| |

- tAlpha thermal dilatation coefficient |

| |

- E Young modulus |

| |

- n Poisson ratio |

| |

- alpha friction coefficient |

| |

- alphaPsi dilatancy coefficient |

| |

- ht hardening type, 1: linear hardening, 2: exponential

hardening |

| |

- iys initial yield stress in shear,  |

| |

- lys limit yield stress for exponential hardening,

|

| |

- hm hardening modulus normalized with E-modulus (!) |

| |

- kc  for the exponential softening law for the exponential softening law |

| |

- yieldtol tolerance of the error in the yield criterion, default value

1.e-14 |

| |

- newtonIter maximum number of iterations in  search, default value 30 search, default value 30 |

| Supported modes |

3dMat, PlaneStrain, 3dRotContinuum |

|

Borek Patzak

2019-03-19

, so the

hardening variable is proportional to the plastic multiplier.

For

, so the

hardening variable is proportional to the plastic multiplier.

For

![]() , given by

, given by