The containment is a massive concrete structure with inner steel lining, heavilly reinforced and prestressed in cylindrical and dome parts.

The problem consists in coupled heat&mass and mechanical analyses. Numerical model of heat&mass transport is based on coupled description of heat and miosture transport, hydration, creep, and shrinkage of concrete by Hellmich et all [1]. The structural analysis uses a constitutive model based on the microprestress-solidification theory by Bazant et al.[2]. The model neglects the influence of strains on transport properties caused by changes in porosity. Thus the analysis has been splitted into two subsequent parts in each solution step: transport and mechanical analysis. The model takes also into account four construction phases.

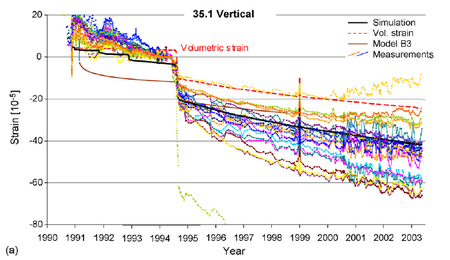

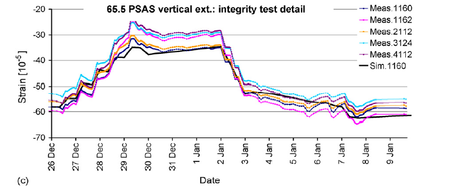

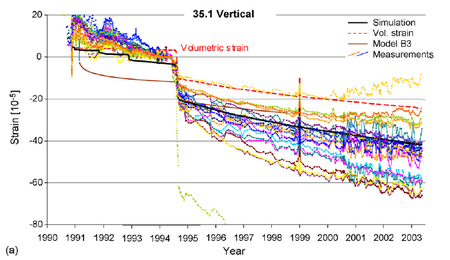

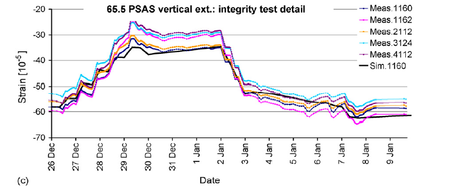

The boundary conditions were taken from NPP monitoring system. At the beginning, constitutive properties were estimated from laboratory experiments or table values. Then the parameters were calibrated using data taken from NPP monitoring system. Systematic recalibration is planned, to enable reliable service life planing. The results, that are presented, consist in strain history compared to measured values from two type of sensors (PLDS placed in concrete and PSAS placed on reinforcement) systematically located in seven height levels and four vertical positions around the containment, measuring strains in vertical, circumferential, and radial directions. in ten years period. For comparison, the computed strain values are shifted according to measured strains at the end of prestressing, because the initial deformation of the fresh concrete cannot be simulated by he present model. The strain scale in all graphs is 10e-5, time is in years.

|  |

|  |

|

After putting the contaiment into a service, deterioration of measurement quality of certain sensors can be observed. Also the boubdary conditions have changed during the time, which has not been fully reflected in the model. Detailed report can be found in [3].

| This page is part of the OOFEM project

documentation (www.oofem.org) (c) 2006 Borek Patzak, e-mail: info@oofem.org |

|